Partially bio-based resin provides superior performance properties at lowest GWP among all PPA in the market

Solvay has extended its diversified portfolio of high-performance polyphthalamide (PPA) compounds with Amodel® Bios, a new family of partially bio-based long-chain PPA products particularly indicated for demanding electrical and electronic applications in e-mobility. Besides its renewable feedstock content from non-food competing sources, it is produced with 100% renewable electricity, minimizing its global warming potential (GWP) well below the level of other bio-based PPA.

Backed by a long history of pioneering PPA innovations, Solvay’s Amodel® Bios PPA combines this exceptional sustainability with outstanding performance properties for components in e-motors, power electronics and other high-end electrical systems. Most notably, it offers the highest glass transition temperature (Tg 135°C) of all bio-based PPA in the market and a melting point (Tm) of 315°C. Designed for injection molding, it is an ideal candidate for non-blistering reflow soldered surface mount devices (SMD) and parts in the cooling circuit of power electronics, including fluid connectors.

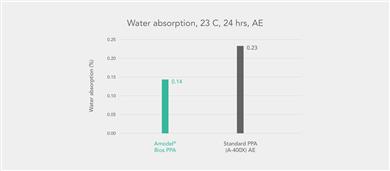

In addition, the limited moisture absorption of the new polymer versus standard PPA results in a high level of dimensional stability at a low risk of stress corrosion, which is particularly important with regard to miniaturized electrical connectors. Amodel® Bios PPA also provides superior impact strength even in halogen-free flame-retarded grades complying with UL94 V0, and is well-suited for colorable applications. This is complemented by high elongation, weld-line strength and excellent surface aesthetics.

“As we continue driving the innovation of PPA to meet the higher performance needs in e-mobility, the introduction of Amodel® Bios PPA also demonstrates Solvay’s commitment to help customers achieve ambitious sustainability targets, which aligns with our One Planet message,” states Brian Baleno, Head of Marketing – Transportation at Solvay Specialty Polymers.

Moreover, Solvay has gone one step further in ensuring the sustainability of the new PPA family with the support of Verisk Maplecroft to assess the sustainable sourcing characteristics of the material. The consultancy’s Commodity Risk Service complemented Solvay’s internal supply chain risk assessment process aimed at identifying and managing risks associated with a multitude of environmental, social and corporate governance (ESG) issues.

Amodel® Bios PPA is globally launched and initially available in four grades differentiated by custom-tailored property profiles for structural, electrification and flame-retardant applications.

www.solvay.com