Advanced amorphous PHA technology will provide plastics manufacturers and consumer products companies with marine, soil and home biodegradable options

CJ BIO, a division of South Korea-based CJ CheilJedang, has introduced PHACT® Marine Biodegradable Polymers based on its proprietary polyhydroxyalkanoate (PHA) technology. Being a part of the solution to change the trajectory of the plastic pollution challenge and preserving the planet is the essence of the PHACT brand. PHACT means (PHA + Act) and CJ Bio is committed to impactful action delivering eco-friendly solutions with their extensive PHA technology platform. The first product of the new line – PHACT A1000P – is an amorphous PHA being produced at CJ BIO’s newly commissioned Pasuruan, Indonesia facility. Currently, this is the only amorphous PHA on the market. Amorphous PHA is a softer, more rubbery version of PHA that offers fundamentally different performance characteristics than the crystalline or semi-crystalline forms that currently dominate the PHA market. For its initial applications, PHACT A1000P will be used as a modifier to other compostable polymers and biopolymers to improve functional and processing characteristics, and for enabling these products to achieve faster rates of biodegradation or composting.

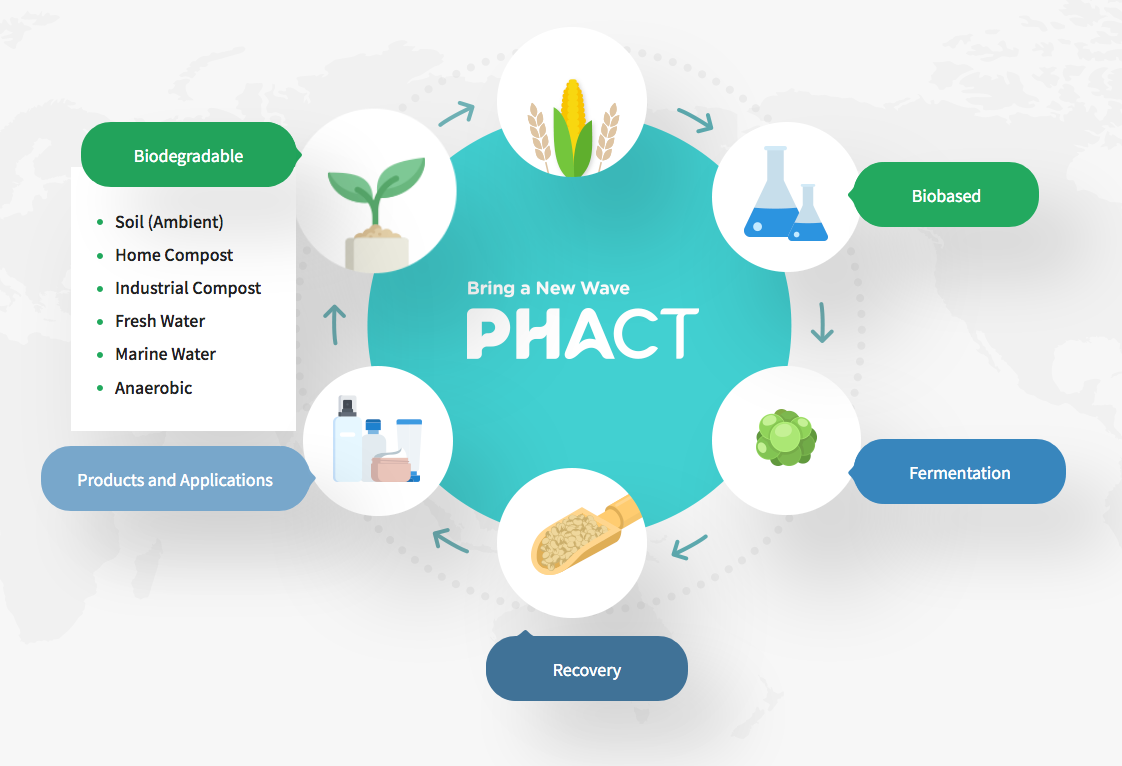

PHACT is certified biodegradable under industrial compost, soil (ambient), and marine environments. It is considered ‘home compostable,’ meaning that it does not require specialized equipment or elevated temperatures to fully degrade. Segments and applications for PHACT are numerous. Immediate focus will be on flexible and rigid packaging, which accounts for greater than 50% of single-use plastics. Other markets include agriculture, organic waste management, coatings and adhesives, personal care and healthcare.

According to Max Senechal, Chief Commercial Officer of the CJ Biomaterials business, the company is looking forward to working with plastic resin producers, compounders, converters and brand owners across multiple segments in putting this technology to work to reduce the impact of plastic waste on the environment. “The world is ready for fully biodegradable bioplastics solutions. Our environment needs it, regulatory agencies support it, and consumers want it,” Senechal said. “Eliminating the harm that petroleum-based plastic waste causes to people’s health and the environment is a project that thousands and thousands of people are working on around the world today. It is something that we can accomplish through working together and the intelligent application of technology. At CJ BIO, we’re excited for the opportunity to introduce people to PHACT and to helping them meet their sustainability goals of a lower carbon footprint and a favorable end-of-life scenario,” he added.

Bio-based and readily biodegradable

The raw materials for PHACT are sugars sourced from plants like sugar cane, tapioca, corn and cellulosic biomass. CJ BIO can increase PHA content in microorganisms from about 5% default accumulation up to 85% through fermentation via engineered microbial strains. The company employs advanced downstream technology for the extraction of PHA components and for the manufacture of specific products.

These PHA products can be compounded and processed using conventional plastics processing equipment. They can also be used as modifiers to other polymers or biopolymers to increase bio-based content, accelerate biodegradation and improve functional properties of resins and finished products.

One promising application is accelerating the rate of composting of the biopolymer polylactic acid (PLA) which has seen significant growth as a bio-based material in a broad range of finished product applications. Blending amorphous PHA in PLA leads to significant improvements in mechanical properties, such as toughness, and ductility, while maintaining clarity.

Developing the applications of tomorrow

According to Raj Krishnaswamy, Vice President Product & Applications Development, CJ BIO is investing substantially in applications capability – both personnel and facilities – to help potential innovation partners develop next-generation solutions. “The applications for this technology are almost unlimited. Whether you’re talking about single-use food and beverage packaging, paper coatings, personal care, , drug delivery systems or medical devices – each solution needs to be developed in collaboration with value chain partners and with performance and cost in mind,” Krishnaswamy said. “What all of these applications have in common is the need for a truly biodegradable solution, and with CJ BIO PHA technology, we believe we can get there,” he added.