Co-organized by TAITRA and TWMA, WOOD TAIWAN 2023 will be held at Taipei Nangang International Exhibition Center, Hall1 from April 4 to 7, echoing the theme - Envision a Greener Future. From production to consumption, WOOD TAIWAN 2023 will showcase how wood is produced, processed, and manufactured in the woodworking machinery industry, and how it is used in a sustainable fashion on the consumer end for environmental protection and energy conservation.

The Green Material of the 21st Century: Wood

Humans cannot live without nature, especially without wood, a natural resource that can be seen everywhere in modern-day wood products: from tables and chairs to beds, furniture and floors. Wood is not only one of the most breathable natural materials, but also one that has been around us for the longest time. As a bioresource, wood is also seen as a green material of the 21st century. As the awareness of net-zero emissions and sustainability grows, wood, one of the few carbon-negative materials, becomes an indispensable resource.

Optimizing the Use of Wood

According to Tu, Qin-Liang, senior consultant of TWMA, trees in primeval forests were cut down on a massive scale in recent decades, bringing destruction to primeval forests. In response to this, many countries imposed bans on cutting trees to protect woodlands. But due to market demand, many regions such as North America have started to put forward plans for large-scale plantations, an attempt to meet the needs of the woodworking industry as well as consumers by taking advantage of man-made forests. In light of this trend, woodworking machinery will play a crucial role in how to utilize such natural resources in a sustainable and effective manner.

The idea of sustainability will be embodied in WOOD TAIWAN 2023: Envision a Greener Future held in April. As a platform for the wood processing and relevant industries to showcase their finest products, WOOD TAIWAN offers various solutions to maximizing the utilization rate of wood. For example, with woodworking machinery optimizing the production line, the utilization rate increases from 30% to 90%. Not only does this approach reduce the waste of raw materials, but it also improves end products’ (e.g., furniture) sustainability.

Featured Product #1: Finger Jointing System

The finger jointing system presented by Cheng Kuang Wood Machinery Works revolutionizes the existing processing procedures. In the past, only the middle part of a tree was taken out, leaving the rest of the tree wasted, but now with the help of finger jointers, processed products such as wood bars can be made from wood residue instead of wood logs. Coupled with the help of clamp carriers, a sizable panel can be produced. The entire process maximizes the wood utilization rate and turns waste into useful materials at the same time.

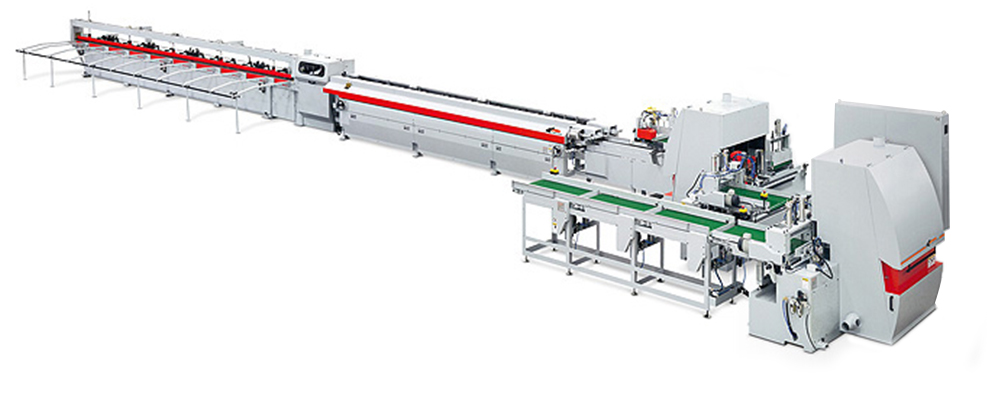

Featured Product #2: Smart Mechanized Nesting Production Line

System furniture, often made of wooden boards, has been gaining popularity in recent years. However, logs are a finite resource and will eventually be depleted. It is therefore important to reuse wood waste and residue, and that is where woodworking machinery comes into play. According to Tommy Lee, general manager of Anderson Group, the largest exhibitor this year, Smart Mechanized Nesting Production Line not only provides materials that meet the international environmental standards, but is also environmentally friendly. The entire production line is upgraded to improve production efficiency and reduce waste, providing the system furniture industry with factory-wide low-error solutions that are efficient, accurate, and manageable. Awarded with the 2022 Taiwan Excellence Award, Smart Mechanized Nesting Production Line maximizes the utilization rate of wood, facilitates clients in transforming from traditional to digital production, increases capacity, and reduces manpower by leaving production work to machines.

Featured Product #3: Panel Machinery

Other essential production equipment for the system furniture industry includes the CNC Machine Center of Lih Woei Carpentry Machine, panel saws of TAI CHAN Machinery, edge banding machines of E-Chain Machinery, and boring machines of ABM Woodworking Machinery.

The CNC Machine Center of Lih Woei saves more energy compared to a traditional one. The motor on traditional machinery starts with full current output when turned on. However, CNC equipment, equipped with an inverter and the feature of detecting processing load, gives an appropriate value of current, which saves more than 40% of electric current compared to traditional machinery. Moreover, CNC can be shut down right after it is done processing without having to stay on standby mode that wastes energy.

ABM Woodworking Machinery, one of the leading manufacturers of boring machines in Taiwan, showcases products with precise boring and lower processing error that refine kitchen cabinet parts. The foolproof products NC Hinge Boring Machine (Speed H32) and NC Construction System Boring Machine (Speed 212) featured in WOOD TAIWAN are extremely user-friendly, where it only takes operators less than 10 minutes to familiarize themselves with the machines, making it flexible for personnel change.

Another feature of ABM’s boring machines is that they are energy conserving. The motor only runs when it is drilling and is deactivated when it is not. The machines are not only energy-saving, but also safe for the operator and people around the machines. In addition, the energy-saving LEDs on the machines help save the overall energy consumption of factories.

The next-gen Automatic Edge Banding Machines developed by E-Chain Machinery is a multifunctional, automatic machine suitable for straight, inclined and partially inclined edges. The machine not only saves energy, but also improves work efficiency at the same time.

TAI CHAN is one of the leading manufacturers of PC control high speed panel saw. The company developed Twin Pusher System with optimized cut function and In-Feed System. Panel saws are used not only for wood processing, but also for processing and cutting a wide range of materials. They are the best energy-saving solution that has better performance, stability, capacity, and efficiency.

www.woodtaiwan.com