At this year’s Battery Show Europe 2021 from November 30 to December 2 in Stuttgart, Germany, SABIC is calling attention to its dedicated and all-encompassing approach to ‘Powering Excellence in Batteries and Energy Storage’ – across industries from automotive and e-mobility to others who rely on stationary energy storage applications. At Booth 6-651, the company is demonstrating its commitment, expertise and broad portfolio of polymer and specialty technologies to help customers implement safer, more sustainable and economically scalable concepts for more efficient energy storage.

“Most countries on this planet are committed to deliver on carbon neutrality ambitions, so accelerating innovation in batteries – from lead-acid to lithium-ion and fuel cells – is key for the world’s transition to clean energy,” says Bob Maughon, Executive Vice President, Sustainability, Technology & Innovation and Chief Technology and Sustainability Officer at SABIC. “Our drive is to power the energy storage value chain with second-to-none application technology, material engineering, regulatory expertise and one of the most comprehensive and focused thermoplastic offerings in the market.”

SABIC’s exhibit at The Battery Show Europe 2021 will highlight a range of polymer solutions targeted at optimizing all structural battery pack components, while also addressing the vast potential to re-imagine specific battery and energy storage applications with advanced engineering thermoplastics. Key visuals will illustrate the overall cost and performance benefits of plastic-intensive designs in terms of energy density, thermal insulation, flame retardancy, impact and chemical resistance, lightweighting, functional integration and dimensional stability.

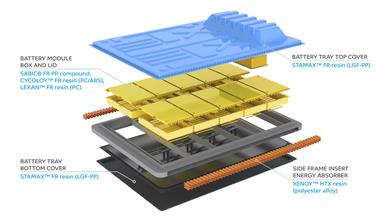

One of the most critical issues especially in the performance of batteries for electrical vehicles (EVs) is the prevention of battery fires in thermal run-away situations. SABIC’s wide range of non-halogenated flame retardant (FR) resins can offer unique intumescent and char-forming properties, delivering the potential to stop the propagation of flames in the case of a fire and eliminate the need for additional thermal blankets, such as those required when using metal designs. At the same time, SABIC’s non-halogenated FR resins provide greater design flexibility, significant weight savings – an important feature for supporting the improved driving ranges of EVs – and recyclability to support the circularity of battery materials (see Figure 1).

Winning Value Propositions Across All Industry Segments

Exhibiting side by side, SABIC’s Petrochemicals and Specialties businesses are taking the opportunity of The Battery Show Europe 2021 to demonstrate how their complementing material portfolios and application development support can help manufacturers reduce system cost and speed the time-to-market of safer and more energy-efficient batteries. An additional focus is material solutions for indoor and outdoor EV charging units, a growing need to meet the growth of the EV fleet.

SABIC’s offerings are targeted at all types of battery components for EVs, E-bikes and industrial vehicles (forklifts, caterpillars) as well as EV charging infrastructure and energy storage systems (ESS).

Featured solutions from the Petrochemicals portfolio at the show will include:

An industry-first, lightweight plug-in hybrid (PHEV) battery tray cover using non-halogenated FR SABIC® PP compound to meet stringent fire safety requirements while eliminating additional thermal blankets vs. aluminum designs (Figure 2)

A prototype of an optimized EV battery pack with novel design solutions and polymers such as STAMAX™ FR resin for up to 12 percent weight savings compared to an existing aluminum EV battery pack

A prototype plastic honeycomb structure in XENOY™ HTX resin for battery pack side impact protection, with significant weight and costs savings vs. metals

Other prototypes and commercial applications of battery and charger housings using engineering thermoplastic and polypropylene compounds, including STAMAX™ FR solutions

12 x 12-inch plates illustrating the superior fire shielding performance of STAMAX FR resin vs. aluminum when exposed to a flame temperature of 1,000°C over five minutes

SABIC’s Everflow joint venture for next-generation vanadium redox flow (VRF) long-duration batteries using SABIC’s polymer grades for key components such as the battery stack, tank and piping, developed and tested with SABIC’s expert team

An innovative energy storage system concept based on second-life EV batteries

An EV charging connector made from VALOX™ FR resin

Powering a New Generation of Energy Storage Solutions

SABIC’s Specialties business will present its vision of re-imagining battery designs for e-mobility and industrial applications with advanced thermoplastic solutions designed to maximize safety, provide longer product life and support manufacturing scalability. Figure 3 illustrates the total high performance resin approach from the top cover to the bottom enclosure of a typical EV battery package. Several SABIC exhibits will demonstrate this in-depth application and material expertise:

New NORYL™ NHP 6011/6012 resins , launched here at The Battery Show Europe 2021, for battery module housings, brackets and frames, with robust flame retardancy and impact resistance

ISCC+ certified bio-renewable ULTEM™ resins – with 10 percent lower carbon footprint compared to fossil-based incumbent materials – for use in gaskets and insulation plates of high-performance industrial batteries

A plastic/metal hybrid battery crash protection honeycomb prototype using NORYL™ GTX resin for significant weight and cost savings vs. metals

Full NORYL™ GTX resin solutions for top covers, corner support plates and other demanding structural battery parts as well as for honeycomb laminate sheet from EconCore for side crash protection of battery units, offering better dimensional stability and lower water absorption compared to honeycomb structures made with currently used thermoplastics

Advanced ELCRES™ HTV150 capacitor film, winner of the prestigious R&D 100 Awards, supporting the transition from conventional silicon (Si)-based semiconductors to next-generation, wide-band-gap technologies based on silicon carbide (SiC) to improve the efficiency of inverter modules in EVs

Selected pilot and commercial applications with LNP™ copolymers, which deliver low temperature ductility, good flow, flame retardancy and laser weldability; featured examples are a forklift battery side plate in LNP™ CX copolymer blend, a charging plug/connector and battery housings for e-bikes in LNP™ EXL copolymer resins