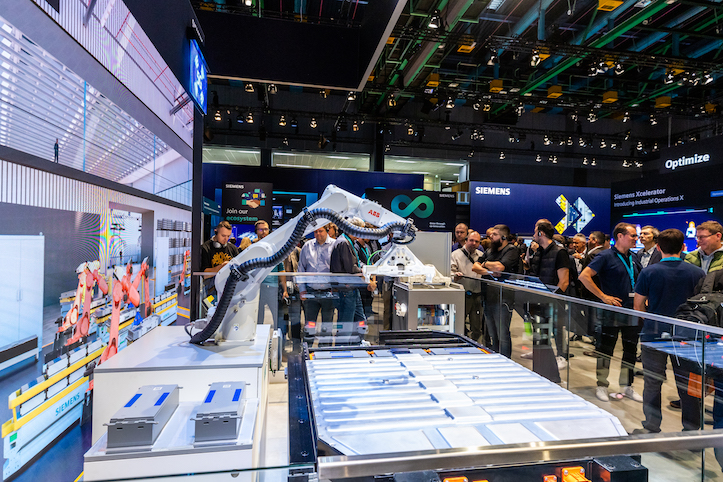

The electromobility industry has been experiencing an unstoppable global upswing for several years. As a result, the demand for electrochemical storage systems is also rising continuously. Lithium-ion battery cells are the central element of the coveted energy storage systems, and the demands placed on their performance, safety and efficiency are correspondingly high.

Deutsch (Germany)

Deutsch (Germany)  Polski (PL)

Polski (PL)