UPM Raflatac has announced Raben and Reganta as the winners of the RafCycle Award at Labelexpo Europe 2023 in Brussels. The RafCycle Award is presented in recognition of their recycling efforts and value chain collaboration.

Sidebar

Recycling

One of Europe’s main recycling hubs for beverage cartons starts operations, backed by Stora Enso and Tetra Pak

State-of-the-art line at Stora Enso’s Polish production site is set to triple the country’s annual recycling capacity of post-consumer beverage cartons

Potential to recycle the entire volume of beverage cartons sold in Poland, with additional volumes from Central and Eastern Europe

By turning used paper-based packaging into new paper-based packaging materials, the line is keeping quality resources in circulation, reducing the use of virgin content

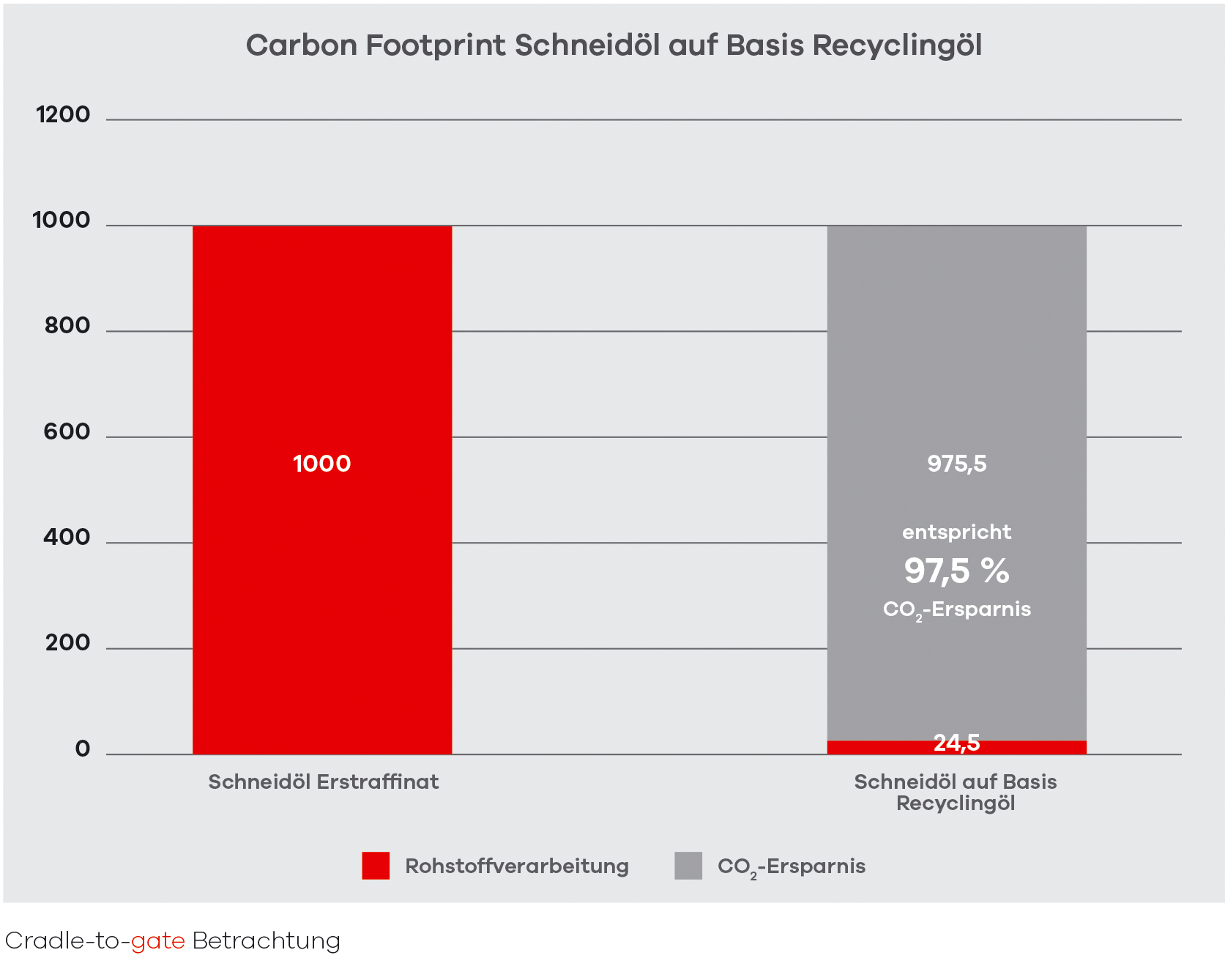

Lubricant in recycling raises the CO2 balance

Lubricant production is energy-intensive. A lot of energy is required to go from the refined crude oil to the finished lubricant. Accordingly, the CO2 balance of motor and hydraulic oil, concrete release agent, cutting and grinding oil does not look exactly rosy. For years, the lubricant specialist Zeller+Gmelin has therefore been making intensive efforts to improve the CO2 footprint: A current example is the production of CO2-optimized industrial lubricants by recycling.

"De-cap" to reuse: a concrete example of circular economy

More and more reuse and recycling schemes for beverage packaging are seen as efficient tools for reducing the environmental impact of packaging systems and for increasing their resource efficiency.

Statement from Polytag on the Government’s response to the Consultation Introducing a Deposit Return Scheme in England, Wales and Northern Ireland

Alice Rackley, CEO of Digital Deposit Return Scheme (DDRS) technology pioneer Polytag, has issued the following statement following the Government’s response to its second consultation for England, Wales and Northern Ireland:

Co-op employs Polytag’s innovative recycling technology for unprecedented traceability of its spring water bottles

Recycling technology innovator, Polytag, is set to apply both unique-every-time QR codes and UV tags to Co-op own-label PET 2-litre spring water bottles in an industry-first, offering the convenience retailer unprecedented visibility of its packaging during the recycling process.

Coveris opens new ReCover recycling facility with pioneering technology

Leading packaging manufacturer Coveris embarks on the next step of its ReCover journey with the opening of a pioneering recycling facility, the second in its portfolio. ReCover, Coveris’ new recycling business segment, is dedicated to closing the loop and keeping plastic circular. The new ReCover plant, located at Coveris’ site in Louth, Lincolnshire (UK), uses ground-breaking technology to recycle printed polyethylene (PE) films.

UPM Specialty Papers introduces the “LinerLoopTM compatible” label to help customers choose release papers that are designed for closed-loop recycling

Resonating with the ambitious EU regulatory targets for reducing waste, UPM Specialty Papers has introduced a new “LinerLoop compatible” label to promote closed loop recycling of release papers used in self-adhesive labels and tapes. Release papers carrying the label qualify for recycling in UPM LinerLoopTM, which is the first commercial-scale closed-loop recycling solution for silicone coated release papers.

Waste and recycling myths busted

In a world beset by a climate crisis, recycling is one low-stakes activity that can make us feel like we're making a difference.

Yes, recycling is yet to be a perfect process, but we owe it to our planet to adopt the best available solutions and continue to develop more effective ones.

New Recyclable Multi-Layer Films by Oliver Healthcare

Talk of sustainability in Medical Device packaging often leads to a discussion about recycling.

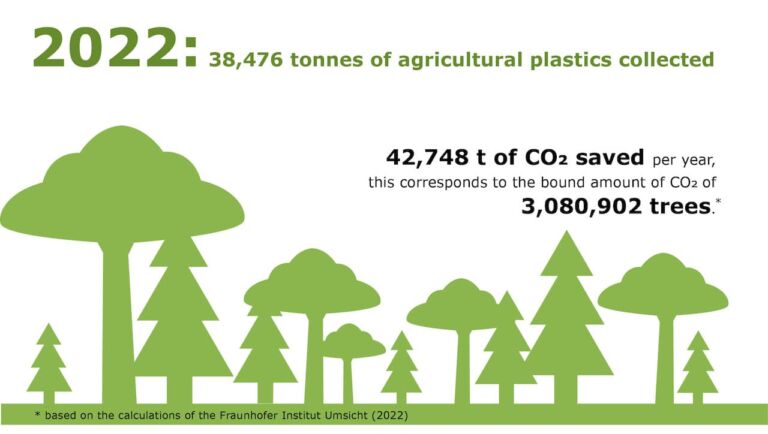

IK-Initiative ERDE fulfils voluntary commitment and collects over 68% of silage and stretch films in Germany

The ERDE (Erntekunststoffe Recycling Deutschland – Crop Plastics Recycling Germany) initiative was again able to significantly increase its collection volumes in 2022. At 645 bring centres and with 3147 on-farm collections, a total of 34 889 tonnes of silage and stretch films were collected and recycled. This corresponds – after deduction of contamination – to 68.7 percent of the silage and stretch films put on the German market. This is confirmed in this year’s annual report to the German Federal Ministry for the Environment, Nature Conservation, Nuclear Safety and Consumer Protection (BMUV).

Deutsch (Germany)

Deutsch (Germany)  Polski (PL)

Polski (PL)