Mitsubishi Electric’s Nagoya Works, one of the company’s main factories developing and manufacturing industrial automation products and systems, introduced a smart visualisation solution to monitor utility data throughout the entire factory. The GENESIS64™ visualisation software, a solution for displaying data in process, infrastructure and manufacturing industries, was leveraged to systematically monitor real-time data remotely from equipment, such as operations and loads, helping to address issues raised by the “new norm”.

Sidebar

Smart

Merck Expands Newest Biologics Testing Center in Shanghai

Further develops its biosafety testing laboratories for local demand; New labs complete 2nd phase of company's €29 million Biologics Testing Center.

Further develops its biosafety testing laboratories to meet local demand

New labs complete 2nd phase of company’s € 29 million Biologics Testing Center opened in 2022

Enhances BioReliance® testing services portfolio in the Chinese market

Avery Dennison Medical to showcase an array of pressure-sensitive adhesives for wearables at Medica 2023

The company also offers global tape solutions with surgical precision

WEVC Announces Partnership with Hydro Extrusions - Cutting Electrical Commercial Embedded Carbon by 50%

Watt Electric Vehicle Company (WEVC), a pioneer in the design, engineering, and manufacture of low-to-medium volume EVs, has partnered with a leading aluminium and energy company committed to a sustainable future to drastically reduce production emissions of its new electric light van.

Tan Delta Systems launches SENSE-2, a new real-time oil monitoring system to significantly reduce operating costs for the manufacturing, machinery and lubrication sector

Tan Delta Systems, a manufacturer of real-time oil quality monitoring sensors and systems is leading the way within the manufacturing and lubrication sector with the launch of SENSE-2. The new oil condition monitoring kit provides real-time data about machine oil quality to optimise maintenance and reduce operating costs.

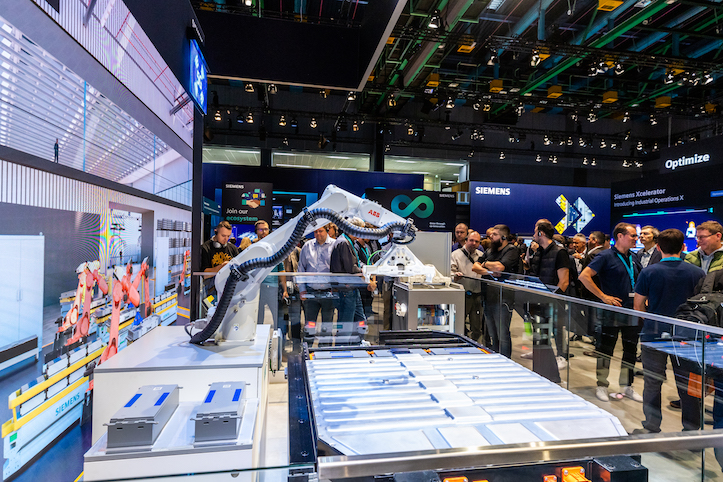

SPS 2023: All about growth

This year’s 32nd edition of the SPS - Smart Production Solutions was an out-and-out success. The number of exhibitors and trade visitors demonstrated the significant growth of the trade fair towards pre-covid levels. The organizer Mesago Messe Frankfurt also made the right call with its decision to expand the exhibition space by adding two new halls.

Alleima starts express program for heat exchanger tubes in EMEA

Eight weeks from order to placement. That is how fast customers that urgently need to replace their heat exchanger tubes, can receive their products, with the highest quality.This is the result of a new express program for Alleima’s customers in Europe Middle East and Africa (EMEA).

FPT Industrial üowers the charge at Iveco Model year 24 range launch

The advanced and sustainable propulsion systems range of FPT Industrial, the Iveco Group brand dedicated to the design, production, and sale of low-environmental impact powertrains, starred at the launch of the new IVECO Model Year 24 range during the IVECO event, held in Barcelona on November 15th.

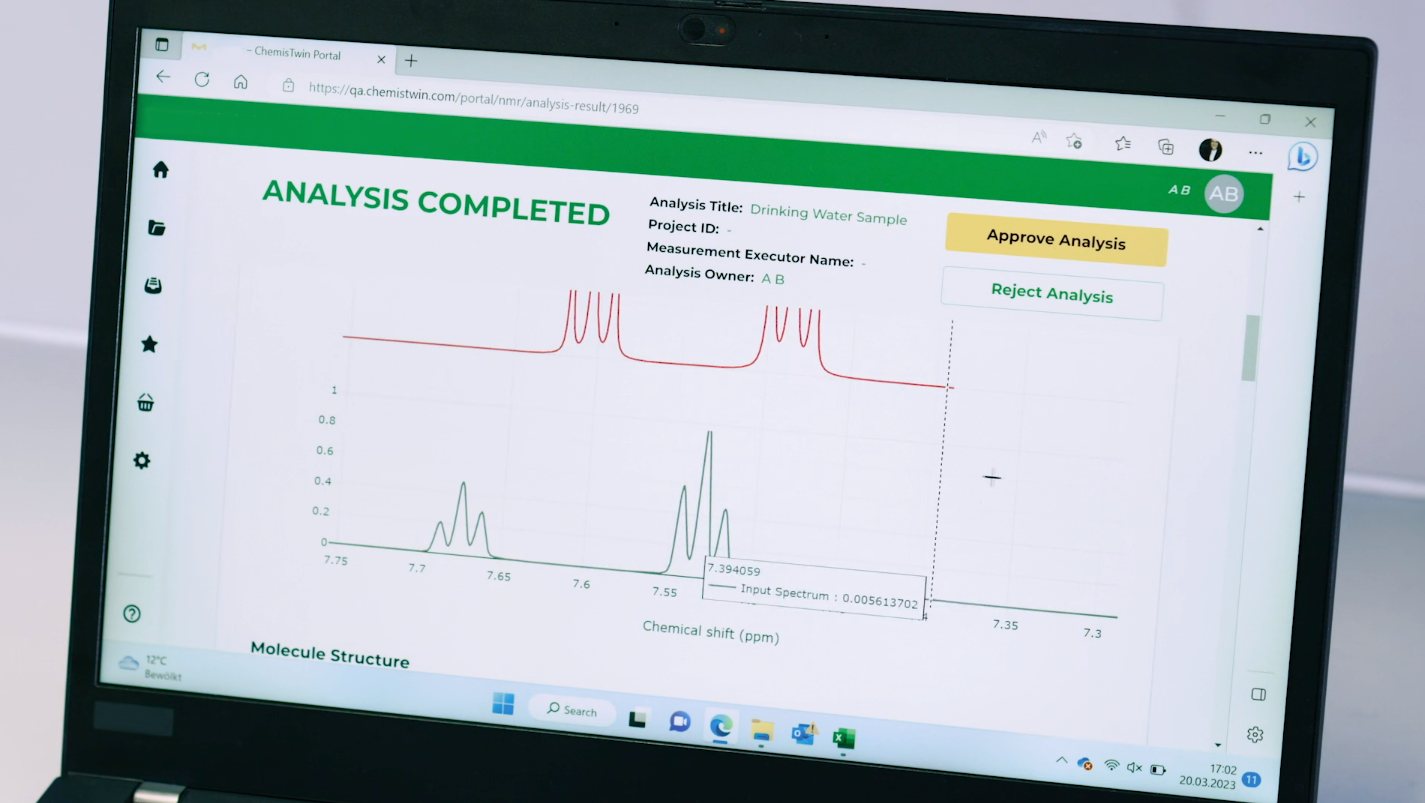

Merck Launches ChemisTwin, First Ever Digital Reference Materials Platform for Analytical Testing

Platform can perform automatic analysis of sample's purity, identification and degradation of compounds through calibrated algorithm-based digital references.

Accelerates digitalization in labs and manufacturing by offering traceable digital records of physical reference materials

Allows Pharma QC/QA and R&D to increase sampling rate and identify sample inconsistencies to ensure safer products

Returner Digital Zone at SPS

The RETUNER DIGITAL ZONE is the digital heart of the stand, the area where we present our digital solutions applied to Nadella products.

Automechanika Frankfurt receives positive feedback on focus topics transformation and sustainability

Registrations for Automechanika Frankfurt 2024 are already around 20 per cent above the level of the previous event one year before the start of the trade fair. The focus topics of transformation and sustainability have also been very well received by the industry: Leading players have already announced that they will be presenting corresponding products and solutions for the aftermarket and original equipment from 10 to 14 September 2024.

Deutsch (Germany)

Deutsch (Germany)  Polski (PL)

Polski (PL)