Bramble Energy’s latest whitepaper reveals system advantages for its groundbreaking PCBFC™ technology

Bramble’s fuel cell stacks streamline system builds, component choices, and integration for simple, efficient and cost-effective systems

Whitepaper highlights how PCBFC™ technology within electric powertrains can reduce or remove power conversion unit

Systems can remove the requirement for de-ionised cooling water loop and the deioniser for lower maintenance and capex cost as well as a further simplified, lower mass, volume and cost system

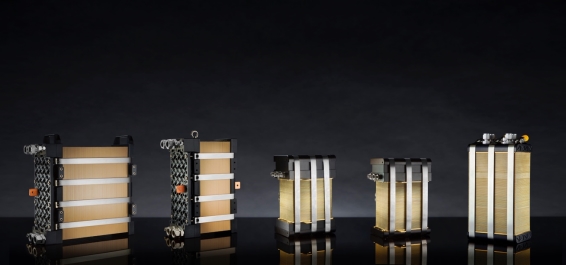

Bramble’s non-conductive modular stacks can be packaged closely together without risk to the stack or user to improve power density and safety.

Revolutionary technology provides a viable route for accessing the hydrogen economy as its PCBFC™ can be manufactured in almost any size or arrangement at much greater speed and scale than traditional electrochemical stacks, at a much lower cost

Bramble Energy, a pioneer in fuel cell technology, is proud to announce the release of its latest whitepaper, detailing the groundbreaking system advantages of its patented Printed Circuit board Fuel Cell (PCBFC™) technology.

Through innovative fuel cell stack design, Bramble Energy has highlighted not only a significant leap forward in cost-effectiveness for hydrogen fuel cell design but also introduces a paradigm shift in simplifying system architectures.

Bramble Energy's core competency lies in the development of PCBFC™ stacks, which have been engineered to overcome the boundaries of conventional fuel cell technology. The result is a low-cost, scalable fuel cell solution applicable across various sectors that offers the pathway to achieving an unprecedented fuel cell stack cost of $60/kW.

In its latest whitepaper, Bramble Energy highlights how its innovative technology extends to system architecture simplification. Bramble’s fuel cell stacks streamline system builds, component choices, and integration with the ultimate goal to empower the hydrogen economy by creating a system that is simple, efficient, and cost-effective.

Less is more

One major advantage when used within an electric powertrain is the reduction or removal of the power conversion unit as current and voltage output of the stack can be customised to meet the application or readily available component specifications. The whitepaper explains that based on operating parameters, it is possible through module design to remove the DC-DC converter altogether to reduce mass, volume, cost and system complexity.

Furthermore, the PCBFC™ allows integrators to remove the deioniser and the complex deionised cooling loop as the cooling channels are not in electrical contact with the stack, and replacing this with a simple water glycol mix coolant. Removing the requirement for de-ionised cooling water loop and the deioniser, results in lower maintenance and capex cost as well as a further simplified, lower mass, volume and cost system required to operate the fuel cell.

Finally, removal of surface protection of the stack as the outer surface is non-conductive and thus allowing for tighter packaging. Utilising the di-electric PCB materials, the PCBFC™ stack reduces the risk of short circuiting. Unlike competitors, Bramble’s modular stacks can be packaged closely together without risk to the stack or user. This in turn improves power density and safety.

Vidal Bharath, Chief Commercial Officer, Bramble Energy said: “Bramble Energy has designed fuel cell stacks that simplify system builds, component choices and integration. In doing so, by using our low-cost stack technology we’ve shown the pathway to the simplest, lowest cost system architecture.

“Our goal is to empower the hydrogen economy, whatever the application. Therefore, as far as we’re concerned, there is little point in having the lowest cost fuel cell stack if the system to run it requires immense complexity and specifically made expensive, bulky, heavy components. A low-cost stack means little without a low-cost system to run it.”

Bramble’s fuel cell technology, the PCBFC™, is a low-cost, scalable solution suitable for use in a range of sectors from transportation to energy storage. The technology uses revolutionary materials and manufacturing methods common within the PCB industry, whilst at its core is a traditional PEM fuel cell MEA. The PCBFC™ leverages the industrial maturity of the PCB industry, resulting in fuel cells that can be manufactured globally, at scale, today. The PCBFC™ can also be manufactured into a multitude of form factors, servicing a variety of customers and use cases across a number of industries and sectors without tooling and manufacturing costs.

Bramble Energy’s technology is providing a generational leap in the global transition to hydrogen as a clean energy source. The company's breakthroughs in cost-effective fuel cell technology have the potential to accelerate the adoption of hydrogen across industries, contributing to a sustainable and green future.

www.brambleenergy.com

Deutsch (Germany)

Deutsch (Germany)  Polski (PL)

Polski (PL)