On March 12 and 13, 2025, the Areal Böhler in Düsseldorf will become the hotspot of the global circular economy. The Circular Valley Convention 2025 will bring together leading players and thought leaders from business, science, politics and society to jointly develop pioneering solutions for the future of the circular economy. With an innovative mix of conference, expo and networking event, the convention offers a cross-industry content hub and a marketplace for circular economy solutions.

Sidebar

Climate

Clariant EnviCa N2O-S catalyst expected to cut 275 KT/Y CO2eq at Sichuan Lutianhua nitric acid plant

EnviCat N2O-S catalyst successfully started up at Sichuan Lutianhua nitric acid plant in August 2024 and estimated to reduce N2O emissions by 275 kilotons of CO2eq

Sichuan Lutianhua was a winner of Clariant’s Climate Campaign, receiving a free load of EnviCat N2O-S catalyst for nitrous oxide (N2O) abatement

This easy-to-install catalyst is proven to remove up to 95% of N2O from the off-gas of nitric acid production plants

Elkem secures EUR 1.8 million EU grant to explore CO2-free silicon production

Elkem ASA has secured EUR 1.8 million in funding from the European Union for the groundbreaking Elkem Sicalo® (Silicon production with carbon looping) project, which aims to eliminate all CO2 emissions from silicon production.

Value of Water – the Conference parallel to ISH 2025

From global vision to action: Pioneering future solutions for clean water and sanitation

Second European Heatcube installation at KALL Ingredients nears completion

Kyoto Group is thrilled to announce rapid progress on our second European Heatcube installation at KALL Ingredients in Hungary. This milestone brings us closer to decarbonizing industrial steam by delivering renewable thermal energy solutions and driving impactful change in how industries harness sustainable power.

How will the glass industry become CO2-neutral by 2045?

In its study “Glass 2045 – Decarbonisation of the Glass Industry”[1] the Federal Association of the Glass Industry (“Bundesverband Glasindustrie e.V.” - BV Glas) in cooperation with Stuttgart University’s Institute of Energy Economics and Rational Energy Use (“Institut für Energiewirtschaft und Rationelle Energieanwendung – IER”) charted and compared three transformation pathways which can lead the energy-intensive glass industry with its direct emissions towards climate neutrality by 2045.

Circular Valley Convention 2025: Announcing first programme highlights and top speakers

On 12 and 13 March 2025, the Areal Böhler in Düsseldorf will turn into a global circular economy hotspot. The Circular Valley Convention 2025 will bring together leading players and thought leaders from business, science, politics and society to jointly develop groundbreaking solutions for the future of the circular economy. With an innovative mix of conference, expo and networking event, the convention offers a cross-industry content hub and a marketplace for circular economy solutions.

Ship & Shore Environmental Completes Multiple Renewable Energy Projects with Major Biogas Companies

As the global biofuel market size is estimated to reach US$284.95 billion by 2030, the focus on sustainability and environmental responsibility has never been more critical. Ship & Shore Environmental, Inc., a global leader in air pollution abatement and energy efficiency solutions, is proud to announce the successful completion of five groundbreaking renewable energy projects across Texas, Tennessee, and Oklahoma with a major Biogas company. These projects highlight our expertise in transforming waste into energy while tackling unique engineering challenges.

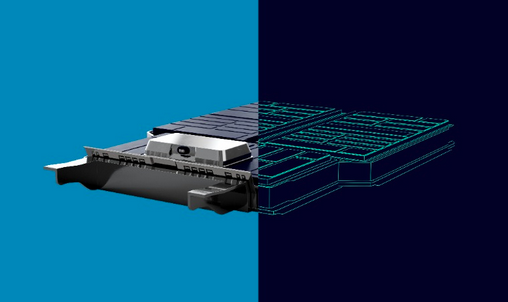

Siemens joins Global Battery Alliance to accelerate development of sustainable battery industry

Siemens Digital Industries Software announced today it has joined the Global Battery Alliance (GBA), a collaboration platform that brings together leading international organizations, NGOs, industry actors, academics and multiple governments to align collectively in a pre-competitive approach, to drive systemic change along the entire battery manufacturing value chain.

Circular Valley Convention 2025: The new global platform for the circular economy

The circular economy relies on reuse, recycling, and innovative business models extending product life cycles. In this way, it helps conserve resources, protect the environment, and mitigate climate change. At the same time, it supports companies in increasing their sustainability, efficiency, and competitiveness. Good reasons, therefore, for the topic of circular economy to take centre stage by gathering all players in one place: at the Circular Valley Convention, which will celebrate its premiere on 12 and 13 March 2025 at Areal Böhler in Düsseldorf.

HANZA wins contract from Munters

HANZA AB has signed an agreement with Munters Europe, a world-leading global supplier of energy efficient and sustainable climate solutions.

Deutsch (Germany)

Deutsch (Germany)  Polski (PL)

Polski (PL)