Hydrogen expert Graebener is expanding its product portfolio and supplying one of the most renowned electrolysis companies with its latest innovation: the stack press.

Graebener Maschinentechnik, a more than 100-year-old special machine construction company, is a specialist in the development of customized systems. With its Graebener Bipolar Plate Technologies division, the Siegerland-based company entered the hydrogen market back in 2003 and has since made a name for itself worldwide. The activities of Graebener Bipolar Plate Technologies focus on the development of technologies and systems for the production of fuel cell and electrolysis components, such as the metallic bipolar plate. Graebener's latest development is a press that is to be used in the manufacturing process of alkaline electrolyzers.

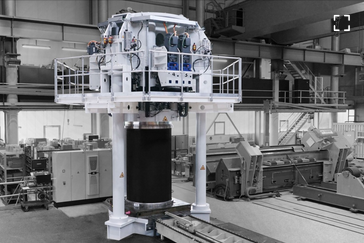

The heart of every electrolyser is its stack, which consists of hundreds of individual or bipolar plates stacked on top of each other. The actual conversion of electrical energy into hydrogen takes place within these stacks. The system that has now been developed supports the technical testing of electrolysis stacks at the end of their production process: the pre-assembled stack, which consists of a large number of plates, is first moved into the machine and compressed to a defined height until a certain pressure is reached within the stack. This pressure must then be maintained unchanged for several hours. During this time, the stack is subjected to all the necessary technical tests by the customer and with the help of other procedures. These are necessary to confirm its full functionality. As soon as the tests have been completed, the stack is finally assembled using tie rods or straps and the finished stack is removed.

Graebener's stack press has a force of 800 tons and can accommodate stacks with a maximum height of around three meters, a maximum diameter of 1.60 meters and a weight of up to 12 tons per stack. In order to ensure maximum safety during assembly work during operation, a hydraulic drive was deliberately omitted. Instead, the stack is compressed inside the press by means of six servomotor-driven spindle units. These are operated in synchronization mode and therefore enable particularly homogeneous compression of the stack. The maximum pressing force per spindle unit is 150 tons.

The biggest challenge, however, was to compensate for production-related stack tolerances. These are unavoidable, but trigger lateral forces when the stack is compressed, which in turn can lead to damage to the stack. In order to prevent this and to create an even pressure distribution within the stack, these lateral forces must be constantly compensated for during the compression of the stack. In Graebener's stack press, this is achieved using short-stroke cylinders, which are located under the six worm gear screw jacks and enable even pressure distribution.

www.hannovermesse.de

Deutsch (Germany)

Deutsch (Germany)  Polski (PL)

Polski (PL)