The HoegTemp heat pump from Enerin in Norway, this year's partner country at HANNOVER MESSE, generates industrial process heat at ultra-high temperatures in an environmentally friendly way. "The most exciting thing about the HoegTemp heat pump is its potential to save 300 billion kilowatt hours of industrial heat in Europe alone," says Arne Høeg, project manager and partner at Enerin.

Heavy industry is responsible for around 22 percent of global carbon dioxide emissions. Around 40 percent of this is a direct result of process heat generation, which in turn results almost exclusively from the combustion of fossil fuels. Greenhouse gas emissions from industrial combustion are therefore higher than global emissions from cars (around 6 percent), and even higher than from all transportation sectors combined (around 14 to 15 percent). This alone illustrates the urgent need for new solutions and technologies to reduce the environmental impact of industrial process heat.

A heat pump with ultra-high temperatures and low CO2 emissions

From Norway, this year's partner country at HANNOVER MESSE, comes Enerin, a company that wants to tackle the problem described above with an all-electric, highly efficient heat pump that can generate temperatures of up to 250 degrees Celsius. According to Enerin, the HoegTemp heat pump with its high efficiency and low energy consumption represents a real breakthrough, as high temperatures are crucial for industries such as food, chemicals and petrochemicals as well as pulp and paper. Until recently, such high temperatures could only be generated using fossil fuels or electric boilers. "Our technology will help to drastically reduce the industry's carbon footprint while lowering operating costs," says Arne Høeg, Project Manager and Partner at Enerin.

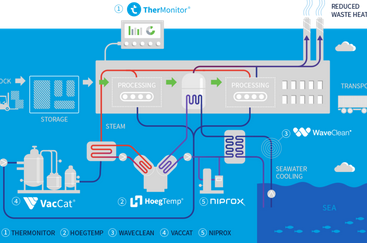

The all-electric HoegTemp heat pump recycles secondary waste heat

One of the technical tricks of the HoegTemp heat pump is the recycling of secondary waste heat, which alone reduces the total energy consumption of such a system by 50 to 70 percent. "Since so much of the CO2 emissions are due to industrial activities, we are pleased that we can make a difference by reusing these emissions," says Høeg.

The HoegTemp heat pump is based on non-toxic helium

HoegTemp's working fluid is helium, an inert, non-toxic gas that neither depletes the ozone layer nor contributes to global warming. "We strive to use environmentally friendly, all-natural and chemical-free solutions in everything we do," explains Høeg. Thanks to its environmental profile, the HoegTemp heat pump has already attracted the attention of industrial players. For example, Pelagia, a Norwegian processor of fish products, wants to eliminate the use of oil and gas-fired steam boilers in the future to make its operations more efficient and sustainable. "The HoegTemp is a promising, reliable, energy-efficient heat pump that can deliver process heat at the temperature we need," confirms Ola Flesland, Product and Process Developer at Pelagia. "When a high-temperature heat pump is powered by electricity from renewable energy sources, we can minimize our carbon footprint from fishmeal and fish oil production."

Competitive price with long-term savings

European industry alone consumes around 500 terawatt hours a year to generate heat between 100 and 200 degrees Celsius. The HoegTemp heat pump should be able to perform this task far more efficiently and at comparatively low cost. According to Enerin, the potential savings amount to around 17 billion US dollars, which actually points to enormous market potential for the patented technology. The HoegTemp heat pump is still in the development stage, but the technology as such is considered mature. The first prototypes have already been installed, and the final product will soon find its way onto the market. "The HoegTemp heat pump will be one of the most cost-effective new technologies on the market," explains Høeg. "Not only will it be competitively priced, but it will also lead to significant long-term savings through reduced energy consumption and lower operating costs."

www.hannovermesse.de

Deutsch (Germany)

Deutsch (Germany)  Polski (PL)

Polski (PL)